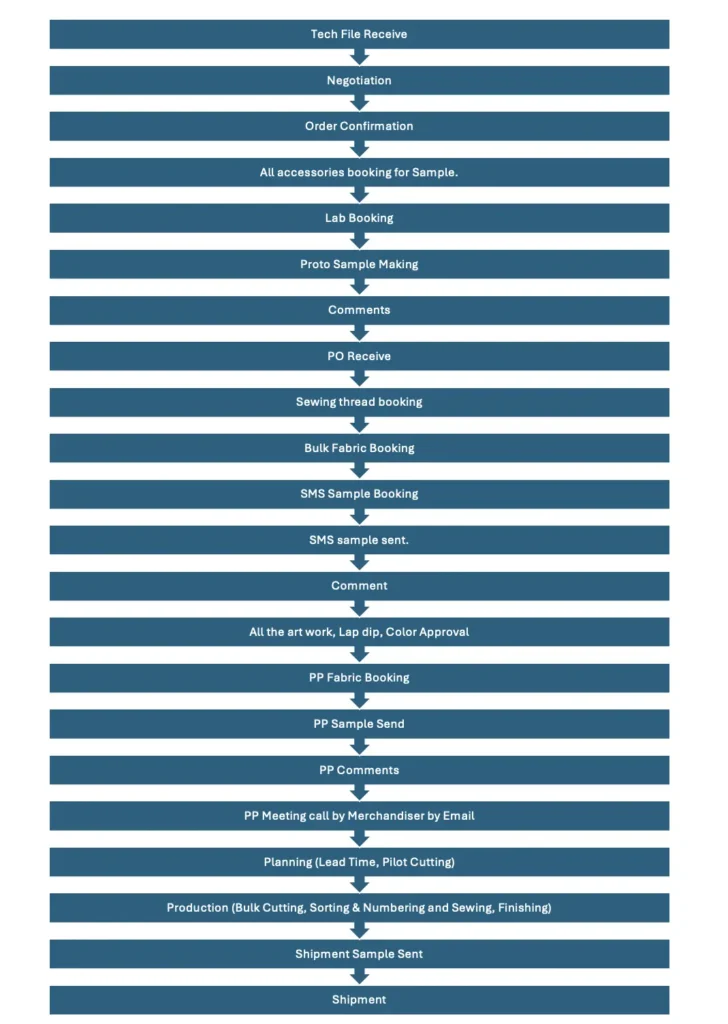

Explore the step-by-step merchandising flow chart for the garment industry, specifically working principal of SGT Major Buyer. Learn the essential merchandising processes from tech file receipt to final shipment, ensuring seamless production and quality control.

Buyer Name: SGT MAJOR

Step-by-Step Merchandising Flow chart

Table of Contents:

1. Tech File Receive

The merchandising process begins when the tech file is received from the buyer. This document includes technical specifications, GSM, Color measurements, materials, and other key details for the product.

2. Negotiation

Initiate negotiations on pricing, delivery timelines, and payment terms with the buyer to align expectations and secure mutual commercial agreements.

3. Order Confirmation

After negotiations, confirm the order with the buyer. This involves contracts and agreeing on final product specifications.

4. Fabrics and Accessories Booking for Sample

Procure or book all necessary fabric and accessories (sewing threads, buttons, zippers, etc.) for making the proto sample. Ensure the accessories meet the buyer’s standards.

5. Lab Booking

Schedule necessary testing for fabrics and accessories in certified in house labs to ensure they meet required standards before bulk production.

6. Proto Sample Making

Develop the proto sample based on the tech file. This sample helps the buyer visualize the final product and confirm specifications.

7. Comments

Recieve mail feedback from the buyer directly or buy a house on the proto sample. Any adjustments or revisions will be noted for the final product.

8. PO Receive

Receive the Purchase Order (PO) from the buyer. This formalizes the order details and enables the next stages of production.

9. Sewing Thread Booking and Accessories

Book sewing thread and other garments accessories according to the specific color and quality required for production, ensuring consistency with the fabric.

10. Bulk Fabric Booking

Place bulk fabric orders based on the buyer’s confirmed fabric quality and color standards. Require GSM, Count, Color and quality has been ensure for sufficient quantities in production.

11. SMS Sample Booking

Block pattern converts into the working pattern by increase grading size wise (S, M, XL, XXL). According to working pattern SMS fabric has been made. Book production for the Salesman Sample (SMS) which will be used by the buyer for sales and marketing purposes.

12. SMS Sample Sent

Send the SMS sample to the buyer’s representative buying the house or directly to the buyer for approval. This sample will be critical for launching sales efforts.

13. Collect Comments

Collect comments from the buyer regarding the SMS sample, adjusting the final production process accordingly.

14. All Artwork, Lap Dip, Color Approval

Secure approvals for all artwork (print, embroidery, etc.), lap dips (color swatches), strike off and color standards from the buyer.

15. PP Fabric Booking

Place orders for Pre-Production (PP) fabric, ensuring it aligns with approved color, quality, and standards.

16. PP Sample Send

Send the PP sample to the buyer or buyer representative for final approval before bulk production begins.

17. PP Comments

Review any comments or adjustments required by the buyer from the PP sample and make necessary corrections.

18. PP Meeting Call by Merchandiser (via Email)

The merchandiser arranges a meeting to discuss any remaining issues or final adjustments before moving to full production.

19. Planning (Lead Time, Pilot Cutting)

Develop a production plan, estimate lead times, and initiate pilot cutting to ensure that the bulk production runs smoothly. Several size set sample has been develop to smoothen the production process.

20. Production

Start bulk production, including:

- Bulk Cutting: Cutting fabrics according to marker.

- Sorting & Numbering: Organizing pieces for accurate assembly.

- Sewing: Assembling the product.

- Finishing: Final finishing touches like ironing, labeling, and packaging.

21. Shipment Sample Sent

Once the bulk production is complete, send a shipment sample to the buyer’s GPQ for final inspection and approval.

22. Shipment

Upon approval, ship the final product to the buyer within the agreed lead time.

Stay tune at Merchandising Diary

Leave a Reply